Turbocharging Fords 2L OHC - Part 2

After doing what I could with my factory engine, 142 rwhp and 198ft/lbs torque I finally aquired all the necessary bitsto build something stronger. Starting with the 205 block that I've preiously mentioned, it was bored 30thou and fitted with TRW forged pistons for 8.44-1 compressions. The bottom end was completely rebuilt.

The new head was firstly crack tested. Then given a monster port job by my good mate Simon here at Retrotech. The head was fitted with some Gp 1 Stainless valves. I kept the previous turbo grind cam.

-Here you can see the new hybrid T25G/13B turbo is significantly larger than my old T25. Also shiner...

I'm pretty happy with the final product. We spent all afternoon trying to start it though. We had a V8 Falcon connected via jumperleads to stop the battrey going flat while we cranked her over. Because last time we had to tow start the engine into life we assumed it just needed more voltage. This was also because it didn't take too much before the battrey would go flat.

...Then it turned out the plug leads were in the wrong sequence! Once that crucial error was corrected it fired into life. Took it down to the local trashing lands...but not before it spat a heater hose on the mainroad....turns out we had forgotton to tighten the hoseclamp....ah the joys of impatience.

The first notable difference was a very smoother acceleration curve. This was partially because it was only running 5psi for running in. So first gear is finally usable again! Power comes in around 3,000rpm and pulls consistantly all the way. I had it still pulling away at 170k's and the power didn't flatten off like it used to. Final power figures can only be speculated at this stage.

-Cosworth GPA top compared to Pinto nice fire rings!

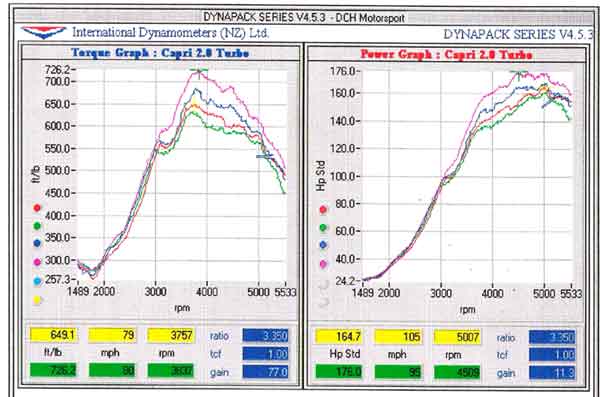

Once we got the capri into DCH Motorsport it was straight on the dyno. The first runs were disapointing managing at best 145hp@rears wheels. Richard from DCH thought 145 was looking pretty good for a pinto until we pointed out that we made that on the last engine. Since we were now running a bigger turbo and twice the boost we expected a significant amount more.

The fuel maps were also all over the place up the top end... Richard took care of this... we got some very strange readings too...We adjusted the Cam gear but it only seemed to make matters worse.

I started to think that the forged pistons and big valves weren't really earning their keep. Simon then suggested that we significantly advance the timing in the boost range. His theory was that pinto engines simply love advance.. more than most would suggest! This instantly jumped the power up to 166 at the rears. Still no signs of detonation either. But the car had now been running consecutive dyno runs for a few hours and was getting pretty hot!

Many thanks to Richard at

DCH Motor Sport 2003 Ltd

19 Washbournes Rd Sockburn

0-3-348 3189

Now we cranked up the boost to 18psi and it pulled out 176hp ATW & 726ft/lbs ATW@3800rpm. Which is 205ft/lbs at the fly. (135kw & 277.9Nm) This was more like it! Very nice torque curve.

After near on 3 hours of dyno time the car was now so piping hot as I stood watching the computer it felt like a furnace behind me. This was not without some damage. The clutch cable went slack and the brake servo began leaking.. it had gotten so hot it had expanded past the seals.

If we'd had a chance to let the car cool down and rid the system of heat soak I'm sure we could have pulled well into the 180+hp ATW.